YIJIAHE Group

-

YIJIAHE Group

- Embodied AI Robot

-

Robot+

Smart Healthcare Smart Cleaning Smart Power Smart Energy Smart Rail Transit

- Group News

- Support

- Join Us

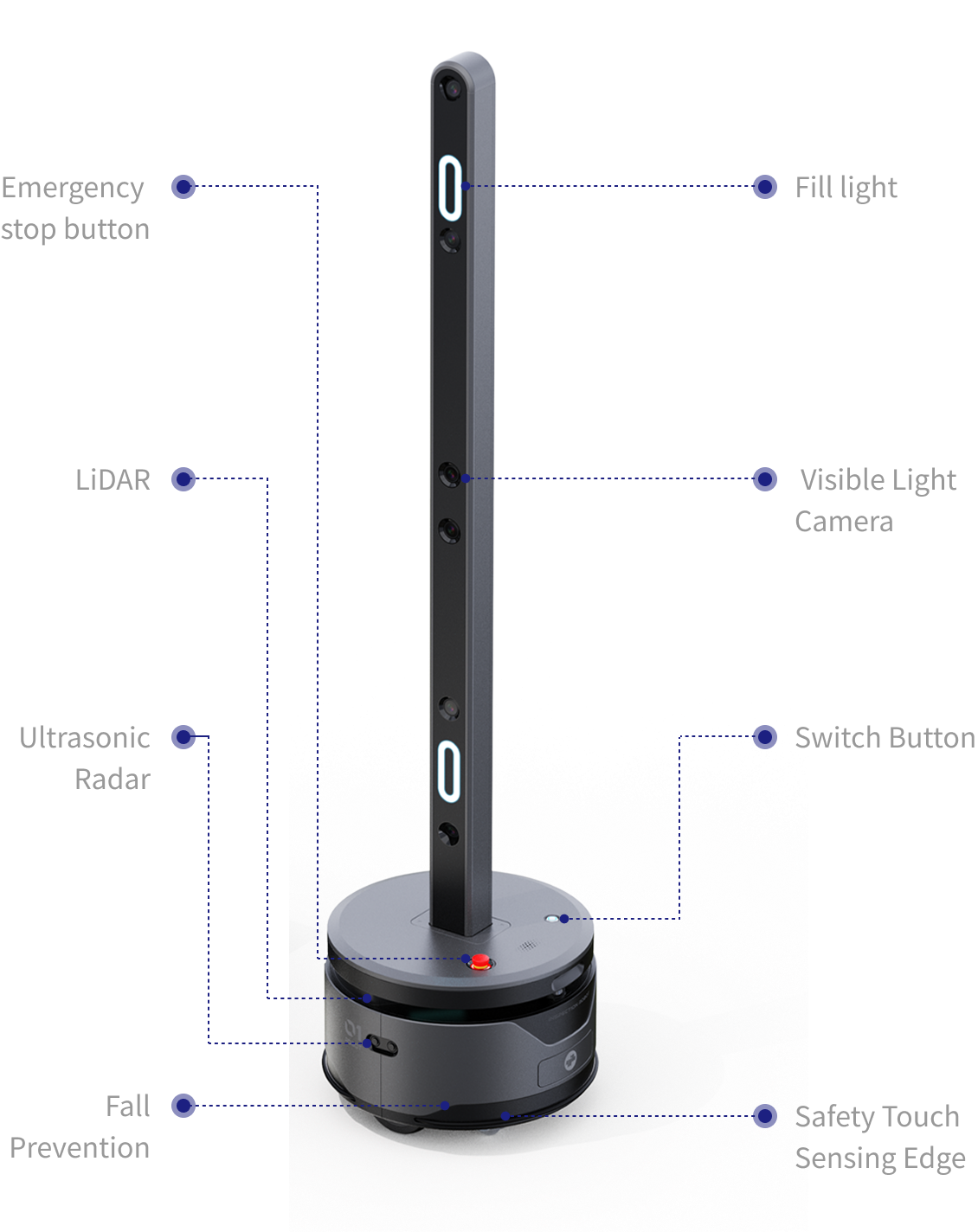

- Investor Relations

The SI300 Intelligent Compact Inspection Robot is suitable for multiple scenarios such as power distribution rooms and switchgear rooms. It features high expandability, can flexibly carry sensors, and realizes functions including environmental monitoring, personnel identification, and voice intercom. It accurately warns of operational risks and fully replaces manual inspection. Designed in accordance with professional technical specifications, it reduces inspection time from 4 hours per station (manual) to less than 30 minutes, improves defect recognition rate to 99%, reduces workload for teams, drives the digital and intelligent transformation of substation operation and maintenance, and supports the high-quality development of the power industry.

Real-time mapping and repeated positioning error ≤ ±20mm; can complete modeling of high-voltage rooms/main control rooms in conventional substations within 30 minutes

Adapts to operating temperatures of -5℃~45℃, and supports a battery life of ≥4 hours in low-temperature environments of -10℃~0℃

Supports autonomous charging pile searching and charging, with multiple protections such as overvoltage/overtemperature/overcharging, enabling unmanned charging management and status monitoring

Adopts a differential drive wheeled chassis; the camera regains stability within 3 seconds during emergency stops, adapting to complex indoor terrains